Introduction

The Recosense IRID-RTLS solution is an inevitable innovation milestone for ambitious smart factories.

RTLS helps enterprises to track, identify, and manage important assets such as tools, personnel, and equipment in real-time by putting a badge/tag on them. Badges/tags utilize wireless technologies such as infrared, ultrasound, Wi-Fi, ZigBee, and RF signals for communication between readers and tags and send signals to the location sensors/readers, which then communicates with a software/middleware platform. This platform analyses the data and correlates useful information to improve staff productivity and operational efficiency in an enterprise environment.

Infrared is the next big thing, today

Infrared light based RTLS system is considered the most innovative in the market leading to the best return on investment in most cases, most industries, and in most applications. Infrared is a simple, easy to handle technology, that eliminates most deficiencies experienced with other technologies. That’s why the Recosense IRID-RTLS can be the next step in transforming your production, in line with Industry 4.0.

Comparison

Active infrared beacon-based systems have been used for room-based location for long. Such system architectures may include only one receiver in every room for a simple, room‐based localization. Cell-of-Origin (CoO) method is applied to get location information. The CoO can be enhanced with additional Angle-of-Arrival (AoA) capabilities for sub‐room precision. This older technology needs several readers to achieve sub-meter accuracy.

The IRID-RTLS technology allows you to use only one receiver to achieve sub cm accuracy. Tags are identified by a pulsing light; the ID is read by the readers with a patent pending algorithm. AoA methodology is used to get the precise location of the tag. For 2D location information, one reader is sufficient and for 3D location, at least two readers are required.

Applications

Recosense IRID-RTLS is currently the most innovative, high accuracy, and best value for money solution for your device, tool and vehicle tracking, motion analysis, resource and work process optimization. Crane tracking and AGV navigation are also potential applications. With RFID integration, the technology is a full-scale solution as a real-time location service for most industrial sectors.

Through a pre-defined interface, the RTLS system provides identification and location data for higher level applications. The enterprise applications support operation and can serve partners or customers with real-time data. The user interface can be tailored to specific needs. The functions range from reports, events, alerts, and actions to an enterprise resource management level. Enterprise software can support thousands of sites, users, and hundreds of thousands of tracked resources.

Connect RTLS data to one or many of these applications to get your operation efficiency to the next level

Application areas

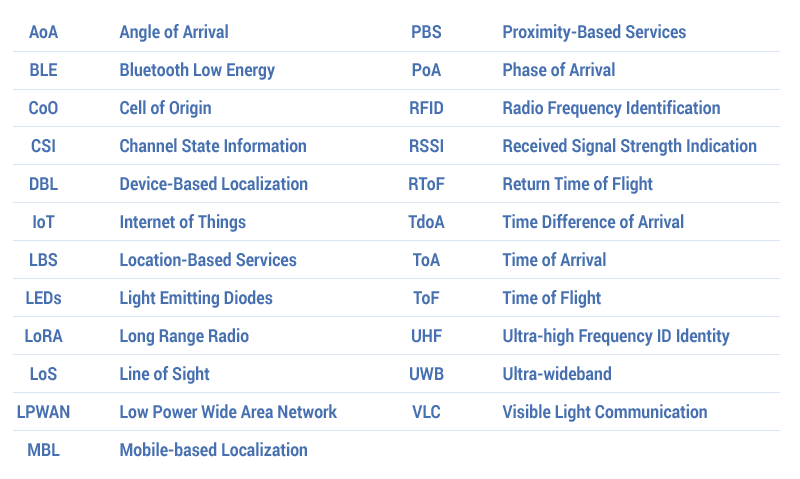

Glossary

Line of Sight

Infrared-Based technology requires a line of sight (LoS) between the tags and the readers (DFMUs). If the tagged assets have to be tracked also, when assets are packed, then IRID-RLTS is not suitable.

In most applications, the readers (DFMUs) are installed on the ceiling facing down. The tags are on the top of the assets.

In any hidden places, additional reader (DFMU) can be installed to track the assets in hidden areas too.

If the reader (DFMU) cannot be installed in a hidden area, the information may be adequate enough where the tag disappeared. (e.g. has been put on a shelf, or into a wardrobe)